Pages

- Home

- Fundamentals of petroleum engineering(1st part)

- Fundamentals of petroleum engineering (2nd part)

- Fundamentals of petroleum engineering

- Basic Petroleum engineering

- Natural Gas Engineering

- Petroleum Economics

- Production Engineering

- Drilling Engineering

- Reservoir Engineering

- Reservoir Characterization

- MSc in Oil and Gas Management

Sunday, 9 October 2016

Enhanced oil recovery

Enhanced oil recovery (abbreviated EOR) is the implementation of various techniques for increasing the amount of crude oil that can be extracted from an oil field. Enhanced oil recovery is also called improved oil recovery or tertiary recovery (as opposed to primary and secondary recovery).

Friday, 19 February 2016

Downhole Motors - Turbines- Turbine Characteristics

Turbine Characteristics

• Torque and RPM are inversely proportional (i.e. as RPM increases,

torque decreases and vice versa).

• RPM is directly proportional to flow rate (at a constant torque).

• Torque is a function of flow rate, mud density, blade angle and the

number of stages, and varies if weight-on-bit varies.

• Optimum power output takes place when thrust bearings are balanced.

• Changing the flow rate causes the characteristic curve to shift.

• Off bottom, the turbine RPM will reach “run away speed” and torque

is zero.

• On bottom, and just at stall, the turbine achieves maximum torque and

RPM is zero.

• Optimum performance is at half the stall torque and at half the

runaway speed, the turbine then achieves maximum horsepower.

• A stabilized turbine used in tangent sections will normally cause the

hole to “walk” to the left.

• Torque and RPM are inversely proportional (i.e. as RPM increases,

torque decreases and vice versa).

• RPM is directly proportional to flow rate (at a constant torque).

• Torque is a function of flow rate, mud density, blade angle and the

number of stages, and varies if weight-on-bit varies.

• Optimum power output takes place when thrust bearings are balanced.

• Changing the flow rate causes the characteristic curve to shift.

• Off bottom, the turbine RPM will reach “run away speed” and torque

is zero.

• On bottom, and just at stall, the turbine achieves maximum torque and

RPM is zero.

• Optimum performance is at half the stall torque and at half the

runaway speed, the turbine then achieves maximum horsepower.

• A stabilized turbine used in tangent sections will normally cause the

hole to “walk” to the left.

Downhole Motors - Turbines- Turbine Observations

Turbine Observations

• There is minimal surface indication of a turbine stalling.

• Turbines do not readily allow the pumping of LCM.

• Sand content of the drilling fluid should be kept to a minimum.

• Due to minimal rubber components, the turbine is able to operate in

high temperature wells.

• Pressure drop through the tool is typically high and can be anything

from 500 psi to over 2000 psi.

• Turbines do not require a by-pass valve.

• Usually, the maximum allowable bearing wear is of the order of 4mm.

• There is minimal surface indication of a turbine stalling.

• Turbines do not readily allow the pumping of LCM.

• Sand content of the drilling fluid should be kept to a minimum.

• Due to minimal rubber components, the turbine is able to operate in

high temperature wells.

• Pressure drop through the tool is typically high and can be anything

from 500 psi to over 2000 psi.

• Turbines do not require a by-pass valve.

• Usually, the maximum allowable bearing wear is of the order of 4mm.

Downhole Motors - Turbines- Directional Turbine

Directional Turbine

This is a short tool which has a set number of stages and its bearing section

entirely within one housing. That is, it is not a sectional tool and will be

typically less than 30 feet long. It is designed for short runs to kick off or

correct a directional well, using a bent sub as the deflection device.

Steerable turbodrills do exist and will be discussed later.

This is a short tool which has a set number of stages and its bearing section

entirely within one housing. That is, it is not a sectional tool and will be

typically less than 30 feet long. It is designed for short runs to kick off or

correct a directional well, using a bent sub as the deflection device.

Steerable turbodrills do exist and will be discussed later.

Downhole Motors - Turbines- Bearing Section

Bearing Section

Usually, thrust bearings are made up of rubber discs (Figure 5-24) which

are non-rotating (being fixed to the outer housing of the tool) and rotating

steel discs attached to the central rotating shaft. Long bearing sections

known as cartridges are used for long life in tangent or straight hole drilling

sections. These are changeable at the rigsite. If the bearings wear past the

maximum point, considerable damage can be inflicted as the steel rotors

will crash into the stators below.

Usually, thrust bearings are made up of rubber discs (Figure 5-24) which

are non-rotating (being fixed to the outer housing of the tool) and rotating

steel discs attached to the central rotating shaft. Long bearing sections

known as cartridges are used for long life in tangent or straight hole drilling

sections. These are changeable at the rigsite. If the bearings wear past the

maximum point, considerable damage can be inflicted as the steel rotors

will crash into the stators below.

Downhole Motors - Turbines- Drive Section

Drive Section

This will consist of a series of bladed stators, fixed to the outer tool housing

and bladed rotors fixed to the central rotating shaft. Mud flow is deflected

at a pre-determined angle off the stator blades to hit the rotor blades and

cause the shaft to rotate. The angle of the blades will affect the torque and

speed output of the turbine

This will consist of a series of bladed stators, fixed to the outer tool housing

and bladed rotors fixed to the central rotating shaft. Mud flow is deflected

at a pre-determined angle off the stator blades to hit the rotor blades and

cause the shaft to rotate. The angle of the blades will affect the torque and

speed output of the turbine

Wednesday, 17 February 2016

Downhole Motors - Turbines

Turbines

A turbine is made up of several sections:

• Drive stages or motor section.

• Axial thrust bearing assembly and radial bearings.

• Bit drive sub.

As stated earlier, the drive stages, or motor section, consists of a series of

stators and rotors of a bladed design. This stator and rotor combination

form a stage. Turbines are referred to as 90 stage, 250 stage, etc. The

number of stages determines the torque generated. Each stage,

theoretically, applies an equal amount of torque to the control shaft and it is

the sum of those torques which will be output to the bit.

The drive sub is simply the bit connection and bearing shaft. Radial

bearings protect the shaft from lateral loading and the thrust bearings

support the downwards hydraulic thrust from mud being pumped through

the tool and the upward thrust of weight being applied to the bit.

Theoretically, weight on bit should be applied to equalize the hydraulic

thrust, which unloads the bearings and prolongs their life.

A turbine is made up of several sections:

• Drive stages or motor section.

• Axial thrust bearing assembly and radial bearings.

• Bit drive sub.

As stated earlier, the drive stages, or motor section, consists of a series of

stators and rotors of a bladed design. This stator and rotor combination

form a stage. Turbines are referred to as 90 stage, 250 stage, etc. The

number of stages determines the torque generated. Each stage,

theoretically, applies an equal amount of torque to the control shaft and it is

the sum of those torques which will be output to the bit.

The drive sub is simply the bit connection and bearing shaft. Radial

bearings protect the shaft from lateral loading and the thrust bearings

support the downwards hydraulic thrust from mud being pumped through

the tool and the upward thrust of weight being applied to the bit.

Theoretically, weight on bit should be applied to equalize the hydraulic

thrust, which unloads the bearings and prolongs their life.

Tuesday, 16 February 2016

Downhole Motors - Positive Displacement Motors : Motor Orientation/Control

Motor Orientation/Control

All directional wells require steering during initial kick offs, correction

runs, sidetracks, and re-drills. Once the desired direction in which the tool

should be faced is determined, the next step is to actually face the tool in

that direction in order to drill the predetermined course.

For the Mach 1/AD motor, a cartridge data transmission (CDT) system has

been developed that allows orientation of the motor in a particular

direction, while still allowing drilling with drillstring rotation. This CDT

system uses a special heavy duty steering tool which provides continuous

surface readout of the drift angle and azimuth, as well as toolface

orientation while drilling ahead.

A “hard wire” from the steering tool, through the drillstring to the surface,

relays the information to computerized surface equipment. Data

transmitted from the steering tool is updated and converted instantly to

information which can be used to make any necessary corrections to the

motor.

All directional wells require steering during initial kick offs, correction

runs, sidetracks, and re-drills. Once the desired direction in which the tool

should be faced is determined, the next step is to actually face the tool in

that direction in order to drill the predetermined course.

For the Mach 1/AD motor, a cartridge data transmission (CDT) system has

been developed that allows orientation of the motor in a particular

direction, while still allowing drilling with drillstring rotation. This CDT

system uses a special heavy duty steering tool which provides continuous

surface readout of the drift angle and azimuth, as well as toolface

orientation while drilling ahead.

A “hard wire” from the steering tool, through the drillstring to the surface,

relays the information to computerized surface equipment. Data

transmitted from the steering tool is updated and converted instantly to

information which can be used to make any necessary corrections to the

motor.

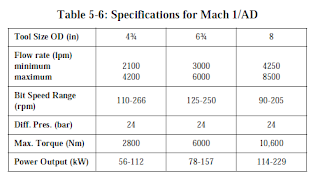

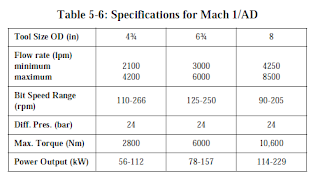

Downhole Motors - Positive Displacement Motors :Navi-Drill Mach 1/AD

Navi-Drill Mach 1/AD

The Navi-Drill Mach 1/AD motor is designed specifically for use in holes

drilled with air and mist. With an AKO, the steerable motor drilling system

combines directional and straight hole drilling capabilities to provide

precise directional control. Generally, in one run it can establish the desired

direction and inclination for the surface interval of a directional well.

The AKO places the bend close to the bit, and can be adjusted so the motor

housing tilt angle can be configured on the rig floor to settings from 0° -

2.5°. The resulting dogleg capability can be as high as 12°/100 ft. The

unique AKO design requires no shims to adjust the bent housing angle, so a

single motor can achieve a variety of build rates.

This motor, with the AKO, can perform directional work when oriented in

a particular direction, and is capable of drilling straight ahead when the

drillstring is rotating. This is accomplished by tilting the bit relative to the

motor and/or applying a side force at the bit while maintaining a minimum

amount of bit offset relative to the axis of the motor.

When an alignment bent sub (ABS) is fitted to the top of the motor and

used in conjunction with the AKO, the motor configuration can be used for

building angle, as in a fixed angle build motor. Orientation of the motor

and drillstring is possible in this configuration, but not rotation. The

maximum build rate possible from this configuration is approximately 20°/

100 ft.

The Navi-Drill Mach 1/AD motor is designed specifically for use in holes

drilled with air and mist. With an AKO, the steerable motor drilling system

combines directional and straight hole drilling capabilities to provide

precise directional control. Generally, in one run it can establish the desired

direction and inclination for the surface interval of a directional well.

The AKO places the bend close to the bit, and can be adjusted so the motor

housing tilt angle can be configured on the rig floor to settings from 0° -

2.5°. The resulting dogleg capability can be as high as 12°/100 ft. The

unique AKO design requires no shims to adjust the bent housing angle, so a

single motor can achieve a variety of build rates.

This motor, with the AKO, can perform directional work when oriented in

a particular direction, and is capable of drilling straight ahead when the

drillstring is rotating. This is accomplished by tilting the bit relative to the

motor and/or applying a side force at the bit while maintaining a minimum

amount of bit offset relative to the axis of the motor.

When an alignment bent sub (ABS) is fitted to the top of the motor and

used in conjunction with the AKO, the motor configuration can be used for

building angle, as in a fixed angle build motor. Orientation of the motor

and drillstring is possible in this configuration, but not rotation. The

maximum build rate possible from this configuration is approximately 20°/

100 ft.

Saturday, 13 February 2016

Downhole Motors - Positive Displacement Motors : Navi-Drill Mach 1 P/HF

Navi-Drill Mach 1 P/HF

The Navi-Drill Mach 1 P/HF (High Torque/High Flow) is a positive

displacement motor that develops high torque at the bit at relatively low to

medium speed range (80-310 RPM). This makes it ideal for directional

applications, drilling with high weight-on-bit, or in areas where formations

require high torque due to specialized PDC bits.

The Navi-Drill Mach 1 P/HF motor has a multi-lobe rotor/stator

configuration which generates more torque than other motors.

A unique bearing assembly and improved elastomer compounds have

increased the Mach 1 P/HF’s hydraulic horsepower and extended its

operating life. The rotor/stator design allows a larger than normal flow rate

to be pumped through the motor, generating the higher torques. There is a

rotor nozzling system that allows the motor to run over the higher

maximum flow rate without exceeding maximum recommended motor

speed. These higher flow rates offer improved hole cleaning and bit

hydraulics.

The Navi-Drill Mach 1 P/HF offers the AKO (adjustable kick off sub)

which is rig floor adjustable between 0° - 2.75°, giving a BUR up to

12°/100 ft. Included in the design is a unique U-joint assembly which

allows the higher torque to be transmitted from the motor section through

the bearing assembly and to the bit.

Although primarily a directional performance drilling motor, the Navi-

Drill Mach 1 P/HF can also be used for straight-hole drilling.

The Navi-Drill Mach 1 P/HF (High Torque/High Flow) is a positive

displacement motor that develops high torque at the bit at relatively low to

medium speed range (80-310 RPM). This makes it ideal for directional

applications, drilling with high weight-on-bit, or in areas where formations

require high torque due to specialized PDC bits.

The Navi-Drill Mach 1 P/HF motor has a multi-lobe rotor/stator

configuration which generates more torque than other motors.

A unique bearing assembly and improved elastomer compounds have

increased the Mach 1 P/HF’s hydraulic horsepower and extended its

operating life. The rotor/stator design allows a larger than normal flow rate

to be pumped through the motor, generating the higher torques. There is a

rotor nozzling system that allows the motor to run over the higher

maximum flow rate without exceeding maximum recommended motor

speed. These higher flow rates offer improved hole cleaning and bit

hydraulics.

The Navi-Drill Mach 1 P/HF offers the AKO (adjustable kick off sub)

which is rig floor adjustable between 0° - 2.75°, giving a BUR up to

12°/100 ft. Included in the design is a unique U-joint assembly which

allows the higher torque to be transmitted from the motor section through

the bearing assembly and to the bit.

Although primarily a directional performance drilling motor, the Navi-

Drill Mach 1 P/HF can also be used for straight-hole drilling.

Downhole Motors - Positive Displacement Motors : Navi-Drill Mach 2

Navi-Drill Mach 2

The Navi-Drill Mach 2 is a positive-displacement motor that can improve

drill rates in both straight-hole and directional applications.

The Mach 2 has a multi-stage, 1/2 rotor/stator configuration, which

generates low to medium torque at medium speeds for higher penetration

rates with less weight-on-bit. This makes it a good choice for drilling

straight and directional holes in difficult formations. The motor is

particularly suited for long-interval performance drilling with natural

diamond, TSP, or PDC bits.

Mach 2 motors also come in 1-3/4”, 2-5/8” and 4-3/4” ODs for slimhole

applications.

Tables 5-3 and 5-4 list the Mach 2 specifications.

The Navi-Drill Mach 2 is a positive-displacement motor that can improve

drill rates in both straight-hole and directional applications.

The Mach 2 has a multi-stage, 1/2 rotor/stator configuration, which

generates low to medium torque at medium speeds for higher penetration

rates with less weight-on-bit. This makes it a good choice for drilling

straight and directional holes in difficult formations. The motor is

particularly suited for long-interval performance drilling with natural

diamond, TSP, or PDC bits.

Mach 2 motors also come in 1-3/4”, 2-5/8” and 4-3/4” ODs for slimhole

applications.

Tables 5-3 and 5-4 list the Mach 2 specifications.

Downhole Motors - Positive Displacement Motors : Navi-Drill Mach 1C

Navi-Drill Mach 1C

The Mach 1C is a positive-displacement motor that develops high torque at

the bit at relatively low speed ranges (80-340 rpm). This makes it ideal for

directional applications, drilling with high weight-on-bit, navigation

drilling with roller cone or large cutter PDC bits, and coring operations.

The motor has a multi-lobe (5/6) rotor/stator configuration, which

generates higher torque than the 1/2 lobe motors, permitting more weighton-

bit and increasing the drill rate. Because the motor develops its power at

low speeds, it can improve bit performance without accelerating wear on

the bearings or cones.

A unique bearing assembly and improved elastomer compounds in the

stator have increased the Mach 1C’s hydraulic horsepower and extended

operating life. It also has a new rotor nozzling system that allows the motor

to be run at 50-100% over its maximum recommended flow rate without

exceeding maximum recommended motor speed. The additional mud

passes through the motor’s rotor, and flow rate can be adjusted by

interchanging nozzles. Higher rates offer improved hole cleaning and bit

hydraulics.

Although primarily a directional performance drilling motor, the Mach 1C

can also be used for straight-hole drilling.

Tables 5-1 and 5-2 detail the Mach 1C specifications.

The Mach 1C is a positive-displacement motor that develops high torque at

the bit at relatively low speed ranges (80-340 rpm). This makes it ideal for

directional applications, drilling with high weight-on-bit, navigation

drilling with roller cone or large cutter PDC bits, and coring operations.

The motor has a multi-lobe (5/6) rotor/stator configuration, which

generates higher torque than the 1/2 lobe motors, permitting more weighton-

bit and increasing the drill rate. Because the motor develops its power at

low speeds, it can improve bit performance without accelerating wear on

the bearings or cones.

A unique bearing assembly and improved elastomer compounds in the

stator have increased the Mach 1C’s hydraulic horsepower and extended

operating life. It also has a new rotor nozzling system that allows the motor

to be run at 50-100% over its maximum recommended flow rate without

exceeding maximum recommended motor speed. The additional mud

passes through the motor’s rotor, and flow rate can be adjusted by

interchanging nozzles. Higher rates offer improved hole cleaning and bit

hydraulics.

Although primarily a directional performance drilling motor, the Mach 1C

can also be used for straight-hole drilling.

Tables 5-1 and 5-2 detail the Mach 1C specifications.

Downhole Motors - Positive Displacement Motors : Characteristics

Characteristics

• Torque is directly proportional to the motor’s differential pressure.

This makes the tool a very simple to operate.

• RPM is directly proportional to flow rate, through somewhat affected

by torque output.

• Hydraulic horsepower consumed = {(P x Q) ¸ 1714}, where P is the

pressure drop (psi) across the motor and Q is flow rate (gpm).

• Torque is directly proportional to the motor’s differential pressure.

This makes the tool a very simple to operate.

• RPM is directly proportional to flow rate, through somewhat affected

by torque output.

• Hydraulic horsepower consumed = {(P x Q) ¸ 1714}, where P is the

pressure drop (psi) across the motor and Q is flow rate (gpm).

Downhole Motors - Positive Displacement Motors : PDM Observations

PDM Observations

• Motor stall will be obvious due to an increase in surface pressure.

Motor stalling should be avoided as it erodes the service life of the

motor.

• LCM can be pumped safely, though care should be taken that the

material is added slowly and evenly dispersed. The system should not

be slugged.

• Sand content in the drilling fluid should be kept to a minimum.

• Temperature limits are around 270°F to 130ºC, but higher temperature

stators have been developed.

• Pressure drop through the tool while working is typically around 50

psi to 800 psi.

• Allowable wear on bearings is of the order of 1mm - 8mm, depending

upon tool size.

• The tool should be flushed out with water prior to laying down.

In general, drilling fluids with a low aniline point can damage the rubber

stator. As a rule, the nailine point in oil based muds should be around

150°F (60°C). Usually, this is related to the aromatic content which should

be equal to or less than 10%. Contact the local supplier if there is any

doubt.

If a by-pass nozzle is fitted to a multi-lobe rotor, then it must be sized very

carefully to allow the motor section to develop the necessary power. Any

variation in flow for which the nozzle was inserted will compromise the

motor’s performance.

• Motor stall will be obvious due to an increase in surface pressure.

Motor stalling should be avoided as it erodes the service life of the

motor.

• LCM can be pumped safely, though care should be taken that the

material is added slowly and evenly dispersed. The system should not

be slugged.

• Sand content in the drilling fluid should be kept to a minimum.

• Temperature limits are around 270°F to 130ºC, but higher temperature

stators have been developed.

• Pressure drop through the tool while working is typically around 50

psi to 800 psi.

• Allowable wear on bearings is of the order of 1mm - 8mm, depending

upon tool size.

• The tool should be flushed out with water prior to laying down.

In general, drilling fluids with a low aniline point can damage the rubber

stator. As a rule, the nailine point in oil based muds should be around

150°F (60°C). Usually, this is related to the aromatic content which should

be equal to or less than 10%. Contact the local supplier if there is any

doubt.

If a by-pass nozzle is fitted to a multi-lobe rotor, then it must be sized very

carefully to allow the motor section to develop the necessary power. Any

variation in flow for which the nozzle was inserted will compromise the

motor’s performance.

Downhole Motors - Positive Displacement Motors : Types of Positive Displacement Motors

Types of Positive Displacement Motors

PDMs come in various configurations. As has been mentioned previously,

the stator will have one more lobe than the rotor. The first types of PDMs,

and the simplest, are 1/2 motors. These generally give medium to low

torque output and medium to high rotary speed. Torque output is directly

proportional to pressure drop across the motor. The

1/2 motors have good applications in performance drilling with a PDC,

diamond, or TSP-type bits. Some shorter models are used for directional

purposes.

Multi-lobe motors have high torque output and relatively slow speed.

Therefore, they have good applications with roller cone bits and for coring.

Such motors are also suitable for use with PDC bits, especially the large

cutter types which require a good torque output to be efficient. These tools,

being fairly short, also have good directional applications with bent subs as

the deflection device. Multi-lobe motors may be constructed with a hollow

rotor and a nozzle or blank placed in a holding device at the top. The nozzle

allows for high flow rates to be accommodated by by-passing the excess

flow from the motor section and the fluid will exit through the bit.

PDMs come in various configurations. As has been mentioned previously,

the stator will have one more lobe than the rotor. The first types of PDMs,

and the simplest, are 1/2 motors. These generally give medium to low

torque output and medium to high rotary speed. Torque output is directly

proportional to pressure drop across the motor. The

1/2 motors have good applications in performance drilling with a PDC,

diamond, or TSP-type bits. Some shorter models are used for directional

purposes.

Multi-lobe motors have high torque output and relatively slow speed.

Therefore, they have good applications with roller cone bits and for coring.

Such motors are also suitable for use with PDC bits, especially the large

cutter types which require a good torque output to be efficient. These tools,

being fairly short, also have good directional applications with bent subs as

the deflection device. Multi-lobe motors may be constructed with a hollow

rotor and a nozzle or blank placed in a holding device at the top. The nozzle

allows for high flow rates to be accommodated by by-passing the excess

flow from the motor section and the fluid will exit through the bit.

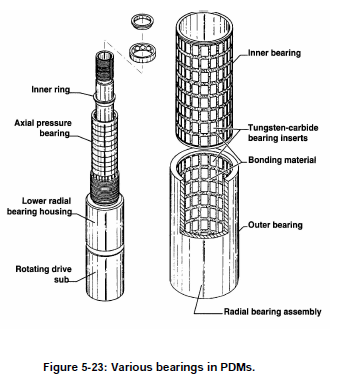

Downhole Motors - Positive Displacement Motors : Bearing Section

Bearing Section

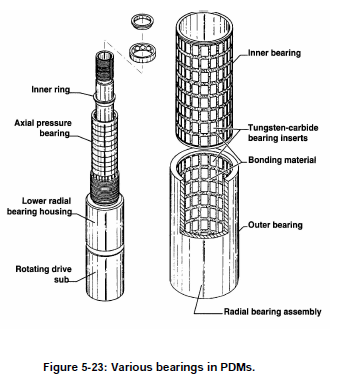

A typical positive displacement motor utilizes three sets of bearings

attached to a drive shaft. There are two sets of radial bearings (“upper” and

“lower”) with one set of axial thrust bearings.

The axial thrust bearing section supports the on and off bottom loading and

hydraulic thrust. It consists of a series of ball bearings stacked one on top

of the other, each set being contained in its own race (groove). The number

of these bearings will vary, depending on the size of the tool.

The upper and lower radial bearings are lined with tungsten carbide inserts.

These bearings support the concentrically rotating drive shaft against

lateral loads. The inherent design of the upper radial bearing limits the

amount of fluid flow diverted to cool and lubricate the bearing package.

This diversion of flow is typically 2 - 10%, depending on motor and bit

pressure drop. The major portion of the drilling fluid is collected by ports

in the drive shaft and exits through the bit. In some motors, diamond

bearings are used, which need up to 20% of the flow to be diverted,

depending upon conditions. Figure 5-23 illustrates typical bearing sections

found in PDMs.

A typical positive displacement motor utilizes three sets of bearings

attached to a drive shaft. There are two sets of radial bearings (“upper” and

“lower”) with one set of axial thrust bearings.

The axial thrust bearing section supports the on and off bottom loading and

hydraulic thrust. It consists of a series of ball bearings stacked one on top

of the other, each set being contained in its own race (groove). The number

of these bearings will vary, depending on the size of the tool.

The upper and lower radial bearings are lined with tungsten carbide inserts.

These bearings support the concentrically rotating drive shaft against

lateral loads. The inherent design of the upper radial bearing limits the

amount of fluid flow diverted to cool and lubricate the bearing package.

This diversion of flow is typically 2 - 10%, depending on motor and bit

pressure drop. The major portion of the drilling fluid is collected by ports

in the drive shaft and exits through the bit. In some motors, diamond

bearings are used, which need up to 20% of the flow to be diverted,

depending upon conditions. Figure 5-23 illustrates typical bearing sections

found in PDMs.

Friday, 12 February 2016

Downhole Motors - Positive Displacement Motors : Connecting rod assemblies

Connecting rod assemblies

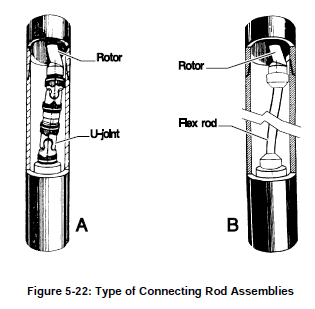

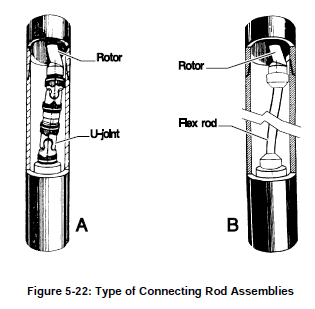

Since the rotor is spiral shaped, it does not rotate concentrically, rather it

traces a back and forth motion. This motion must be converted to a

concentric motion to be transmitted to the bit via the drive sub. This is

achieved by a connecting rod assembly. There are several types.

Universal-joint

U-joint assemblies (Figure 5-22a) have been utilized by the industry and

are still used in most positive displacement motors. The assembly consists

of two universal joints, each grease filled, and sealed with oil-resistant

reinforced rubber sleeves to protect them from drill fluid contamination. A

drawback of the U-joint assembly is the lack of sufficient strength for

higher torque applications, such as those encountered with recent

generations of high torque PDM’s, particularly when used with PDC bits.

This inherent weakness is a result of the manufacturing process whereby

the U-joint is “flame-cut” rather than machined.

Flex rod

A recent development in connecting rod assembly technology has been the

utilization of flexible steel or titanium “flex rods” (Figure 5-22b). While

flex rods are limited by the degree of allowable lateral bending, they have

the advantage of low maintenance, since they do not require lubricants or

rubber sleeves. Flex rods are now standard on most smaller Navi-Drills.

One recent approach has been to mount the flex rod inside the hollow rotor

of a short, high torque steerable PDM, rather than connecting it to the

bottom of the rotor. By connecting a long flex rod to the inside of the top

end of the rotor and extending it through the rotor, to connect to the top of

the drive sub assembly, the overall rate of bend is decreased due to its

increased length.

Since the rotor is spiral shaped, it does not rotate concentrically, rather it

traces a back and forth motion. This motion must be converted to a

concentric motion to be transmitted to the bit via the drive sub. This is

achieved by a connecting rod assembly. There are several types.

Universal-joint

U-joint assemblies (Figure 5-22a) have been utilized by the industry and

are still used in most positive displacement motors. The assembly consists

of two universal joints, each grease filled, and sealed with oil-resistant

reinforced rubber sleeves to protect them from drill fluid contamination. A

drawback of the U-joint assembly is the lack of sufficient strength for

higher torque applications, such as those encountered with recent

generations of high torque PDM’s, particularly when used with PDC bits.

This inherent weakness is a result of the manufacturing process whereby

the U-joint is “flame-cut” rather than machined.

Flex rod

A recent development in connecting rod assembly technology has been the

utilization of flexible steel or titanium “flex rods” (Figure 5-22b). While

flex rods are limited by the degree of allowable lateral bending, they have

the advantage of low maintenance, since they do not require lubricants or

rubber sleeves. Flex rods are now standard on most smaller Navi-Drills.

One recent approach has been to mount the flex rod inside the hollow rotor

of a short, high torque steerable PDM, rather than connecting it to the

bottom of the rotor. By connecting a long flex rod to the inside of the top

end of the rotor and extending it through the rotor, to connect to the top of

the drive sub assembly, the overall rate of bend is decreased due to its

increased length.

Downhole Motors - Positive Displacement Motors : Motor Section

Motor Section

This is a reverse application of Rene Moineau’s pump principle. The motor

section consists of a rubber stator and steel rotor. The simple type is a

helical rotor which is continuous and round. This is the single lobe type.

The stator is molded inside the outer steel housing and is an elastometer

compound. The stator will always have one more lobe than the rotor.

Hence motors will be described as 1/2, 3/4, 5/6 or 9/10 motors.

Both rotor and stator have certain pitch lengths and the ratio of the pitch

length is equal to the ratio of the number of lobes on the rotor to the

number of lobes on the stator.

As mud is pumped through the motor, it fills the cavities between the

dissimilar shapes of the rotor and stator. The rotor is forced to give way by

turning or, in other words, is displaced (hence the name). It is the rotation

of the rotor shaft which is eventually transmitted to the bit.

This is a reverse application of Rene Moineau’s pump principle. The motor

section consists of a rubber stator and steel rotor. The simple type is a

helical rotor which is continuous and round. This is the single lobe type.

The stator is molded inside the outer steel housing and is an elastometer

compound. The stator will always have one more lobe than the rotor.

Hence motors will be described as 1/2, 3/4, 5/6 or 9/10 motors.

Both rotor and stator have certain pitch lengths and the ratio of the pitch

length is equal to the ratio of the number of lobes on the rotor to the

number of lobes on the stator.

As mud is pumped through the motor, it fills the cavities between the

dissimilar shapes of the rotor and stator. The rotor is forced to give way by

turning or, in other words, is displaced (hence the name). It is the rotation

of the rotor shaft which is eventually transmitted to the bit.

Downhole Motors - Positive Displacement Motors : By-Pass Valve

By-Pass Valve

The by-pass valve allows fluid to fill the drill string while tripping in the

hole and to drain while tripping out. When mud is pumped, the valve closes

causing fluid to move through the tool. Most valves are of a spring piston

type which closes under pressure to seal off ports to the annulus. When

there is no downward pressure, the spring forces the piston up so fluid can

channel through the ports to the annulus. (Figure 5-20).

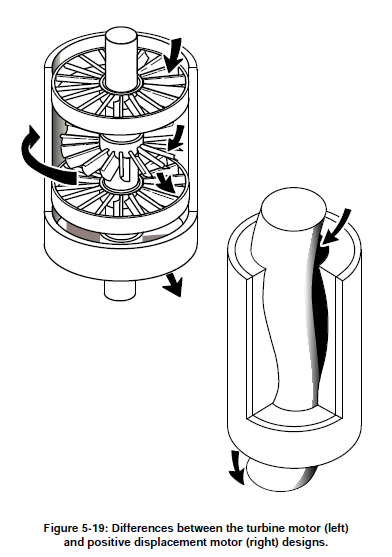

Downhole Motors - Positive Displacement Motors

Positive Displacement Motors

A positive displacement motor (PDM) is a hydraulically driven downhole

motor that uses the Moineau principle to rotate the bit, independent of drill

string rotation. The PDM is made up of several sections:

• By-pass valve or dump sub.

• Motor section.

• Universal joint or connecting rod section.

• Bearing section with drive sub.

A positive displacement motor (PDM) is a hydraulically driven downhole

motor that uses the Moineau principle to rotate the bit, independent of drill

string rotation. The PDM is made up of several sections:

• By-pass valve or dump sub.

• Motor section.

• Universal joint or connecting rod section.

• Bearing section with drive sub.

Downhole Motors

Downhole Motors

The idea of using downhole motors to directly turn the bit is not a new one.

One of the first commercial motors was turbine driven. The first patent for

a turbodrill existed in 1873. The USSR focused efforts in developing

downhole motors as far back as the 1920’s and has continued to use motors

extensively in their drilling activity. After 1945, the West focused efforts

more on rotary drilling, but field applications for downhole motors has

increased spectacularly from the 1980’s onwards.

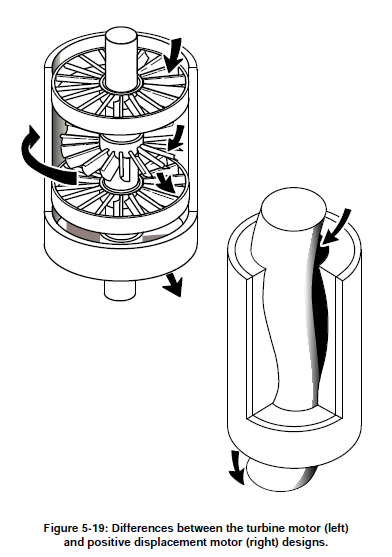

A turbine consists of a multistage vane-type rotor and stator section, a

bearing section, a drive shaft and a bit rotating sub. A “stage” consists of a

rotor and stator of identical profile. The stators are stationary, locked to the

turbine body, and deflect the flow of drilling mud onto the rotors which are

locked to the drive shaft. As the rotors are forced to turn, the drive shaft is

also forced to turn, causing the bit sub and the bit to rotate

The idea of using downhole motors to directly turn the bit is not a new one.

One of the first commercial motors was turbine driven. The first patent for

a turbodrill existed in 1873. The USSR focused efforts in developing

downhole motors as far back as the 1920’s and has continued to use motors

extensively in their drilling activity. After 1945, the West focused efforts

more on rotary drilling, but field applications for downhole motors has

increased spectacularly from the 1980’s onwards.

A turbine consists of a multistage vane-type rotor and stator section, a

bearing section, a drive shaft and a bit rotating sub. A “stage” consists of a

rotor and stator of identical profile. The stators are stationary, locked to the

turbine body, and deflect the flow of drilling mud onto the rotors which are

locked to the drive shaft. As the rotors are forced to turn, the drive shaft is

also forced to turn, causing the bit sub and the bit to rotate

Thursday, 11 February 2016

Proximity (anti-collision) analysis

Proximity (anti-collision) analysis

On multi-well projects (particularly offshore) there are small distances

between slots. To eliminate the risk of collisions directly beneath the

platform, the proposed well path is compared to existing and other

proposed wells. The distances between the other wells and the proposal are

calculated at frequent intervals in critical sections. These calculations can

be performed using the EC*TRAK software (BHI) or COMPASS.

Survey uncertainty must also be computed for both the proposed well and

the existing wells. All major operating companies have established criteria

for the minimum acceptable separation of wells, which are usually linked

to “cone of error” or “ellipse of uncertainty” calculations.

On multi-well projects (particularly offshore) there are small distances

between slots. To eliminate the risk of collisions directly beneath the

platform, the proposed well path is compared to existing and other

proposed wells. The distances between the other wells and the proposal are

calculated at frequent intervals in critical sections. These calculations can

be performed using the EC*TRAK software (BHI) or COMPASS.

Survey uncertainty must also be computed for both the proposed well and

the existing wells. All major operating companies have established criteria

for the minimum acceptable separation of wells, which are usually linked

to “cone of error” or “ellipse of uncertainty” calculations.

Nudging - Planning a nudge program

Planning a nudge program

The directions in which the wells are “nudged'' should be chosen to achieve

maximum separation. Wells may not necessarily be nudged in their target

directions.

Nudges will not only be shown on the individual well plans for each well,

but a structure plot will also be drawn which will show well positions at the

surface casing point after the nudge.

The directions in which the wells are “nudged'' should be chosen to achieve

maximum separation. Wells may not necessarily be nudged in their target

directions.

Nudges will not only be shown on the individual well plans for each well,

but a structure plot will also be drawn which will show well positions at the

surface casing point after the nudge.

Nudging - Techniques for “nudging”

Techniques for “nudging”

When formations are suitable (soft), jetting is the best technique to use.

The most common method is to use a mud motor of 9.5" OD or greater

with a 17.5" bit and a 1.5° bent sub. Using a 1.5° bent sub gives low build

rates and hence a low dogleg severity. The hole is then opened to the

required size after the mud motor run. Occasionally the job is performed

with a large mud motor and a 26" bit from the start. In this case either a

1.5°or 2° bent sub might be used.

When formations are suitable (soft), jetting is the best technique to use.

The most common method is to use a mud motor of 9.5" OD or greater

with a 17.5" bit and a 1.5° bent sub. Using a 1.5° bent sub gives low build

rates and hence a low dogleg severity. The hole is then opened to the

required size after the mud motor run. Occasionally the job is performed

with a large mud motor and a 26" bit from the start. In this case either a

1.5°or 2° bent sub might be used.

Nudging

Nudging

The technique of “nudging” is used on platforms in order to “spread out”

conductors and surface casings, which minimizes the chance of a collision.

Basically, when the hole for surface casing is drilled, some angle is built at

a low rate (e.g. 1°/100') in the chosen direction.

In addition to “spreading things out”, other reasons for “nudging” are:

• to drill from a slot located on the opposite side of the platform from

the target, when there are other wells in between

• to keep wells drilled in the same general direction as far apart as

possible

• if the required horizontal displacement of a well is large compared to

the total vertical depth, then it is necessary to build angle right below

the surface conductor to avoid having to use a high build rate

The technique of “nudging” is used on platforms in order to “spread out”

conductors and surface casings, which minimizes the chance of a collision.

Basically, when the hole for surface casing is drilled, some angle is built at

a low rate (e.g. 1°/100') in the chosen direction.

In addition to “spreading things out”, other reasons for “nudging” are:

• to drill from a slot located on the opposite side of the platform from

the target, when there are other wells in between

• to keep wells drilled in the same general direction as far apart as

possible

• if the required horizontal displacement of a well is large compared to

the total vertical depth, then it is necessary to build angle right below

the surface conductor to avoid having to use a high build rate

Planning The Well Trajectory - Lead angle

Lead angle

In the old days (pre 1985) it was normal practice to allow a “lead angle”

when kicking off. Since roller cone bits used with rotary assemblies tend to

“walk to the right”, the wells were generally kicked off in a direction

several degrees to the left of the target direction. In extreme cases the lead

angles could be as large as 20°.

The greatly increased use of steerable motors and PDC bits for rotary

drilling have drastically reduced the need for wells to be given a “lead

angle”. Many wells today are deliberately kicked off with no lead angle

(i.e. in the target direction).

In the old days (pre 1985) it was normal practice to allow a “lead angle”

when kicking off. Since roller cone bits used with rotary assemblies tend to

“walk to the right”, the wells were generally kicked off in a direction

several degrees to the left of the target direction. In extreme cases the lead

angles could be as large as 20°.

The greatly increased use of steerable motors and PDC bits for rotary

drilling have drastically reduced the need for wells to be given a “lead

angle”. Many wells today are deliberately kicked off with no lead angle

(i.e. in the target direction).

Planning The Well Trajectory - The horizontal projection

The horizontal projection

On many well plans, horizontal projection is just a straight line drawn from

the slot to the target. On multi-well platforms however, it is sometimes

necessary to start the well in a different direction to avoid other wells. Once

clear of these, the well is turned to aim at the target. This is a 3-dimensional

turn, but on the horizontal plan it would typically look like Figure 5-18.

The path of the drilled well is plotted on the horizontal projection by

plotting total North/South coordinates (Northings) versus total East/West

coordinates (Eastings). These coordinates are calculated from surveys.

On many well plans, horizontal projection is just a straight line drawn from

the slot to the target. On multi-well platforms however, it is sometimes

necessary to start the well in a different direction to avoid other wells. Once

clear of these, the well is turned to aim at the target. This is a 3-dimensional

turn, but on the horizontal plan it would typically look like Figure 5-18.

The path of the drilled well is plotted on the horizontal projection by

plotting total North/South coordinates (Northings) versus total East/West

coordinates (Eastings). These coordinates are calculated from surveys.

Planning The Well Trajectory - Drop-off section

Drop-off section

On S-type wells, the rate of drop off is selected to ease casing problems and

avoidance of completion and production problems. It is much less critical

to drilling because there is less tension in the drill pipe that is run through

deeper doglegs and less time spent rotating below the dogleg.

On S-type wells, the rate of drop off is selected to ease casing problems and

avoidance of completion and production problems. It is much less critical

to drilling because there is less tension in the drill pipe that is run through

deeper doglegs and less time spent rotating below the dogleg.

Planning The Well Trajectory - Tangent Section

Tangent Section

During the eighties, a number of extended reach projects were successfully

completed. If wells are drilled at inclinations (up to 80°), the area which

can be covered from a single platform is approximately 8 times that

covered when maximum inclination of the wells is limited to 60°.

However, high inclination angles can result in excessive torque and drag on

the drill string and present hole cleaning, logging, casing, cementing and

production problems. These can generally be avoided with current

technology.

Experience over the years has shown that directional control problems are

aggravated when tangent inclinations are less than 15°. This is because

there is more tendency for the bit to walk (i.e. change in azimuth) so more

time is spent keeping the well on course. As such, most run-of-the-mill

directional wells are still planned with inclinations in the range 15° - 60°.

During the eighties, a number of extended reach projects were successfully

completed. If wells are drilled at inclinations (up to 80°), the area which

can be covered from a single platform is approximately 8 times that

covered when maximum inclination of the wells is limited to 60°.

However, high inclination angles can result in excessive torque and drag on

the drill string and present hole cleaning, logging, casing, cementing and

production problems. These can generally be avoided with current

technology.

Experience over the years has shown that directional control problems are

aggravated when tangent inclinations are less than 15°. This is because

there is more tendency for the bit to walk (i.e. change in azimuth) so more

time is spent keeping the well on course. As such, most run-of-the-mill

directional wells are still planned with inclinations in the range 15° - 60°.

Wednesday, 10 February 2016

Planning The Well Trajectory - Kick-off Point and Build-Up Rate

Kick-off Point and Build-Up Rate

The selection of both the kick-off point and the build-up rate depends on

many factors. Several being hole pattern, casing program, mud program,

required horizontal displacement and maximum tolerable inclination.

Choice of kick-off points can be limited by requirements to keep the well

path at a safe distance from existing wells. The shallower the KOP and the

higher the build-up rate used, the lower the maximum inclination.

Build-up rates are usually in the range 1.5°/100' M.D. to 4.0°/100' M.D. for

normal directional wells. Maximum permissible dogleg severity must be

considered when choosing the appropriate rate.

In practice, well trajectory can be calculated for several KOPs and build-up

rates and the results compared. The optimum choice is one which gives a

safe clearance from all existing wells, keeps the maximum inclination

within desired limits and avoids unnecessarily high dogleg severities.

The selection of both the kick-off point and the build-up rate depends on

many factors. Several being hole pattern, casing program, mud program,

required horizontal displacement and maximum tolerable inclination.

Choice of kick-off points can be limited by requirements to keep the well

path at a safe distance from existing wells. The shallower the KOP and the

higher the build-up rate used, the lower the maximum inclination.

Build-up rates are usually in the range 1.5°/100' M.D. to 4.0°/100' M.D. for

normal directional wells. Maximum permissible dogleg severity must be

considered when choosing the appropriate rate.

In practice, well trajectory can be calculated for several KOPs and build-up

rates and the results compared. The optimum choice is one which gives a

safe clearance from all existing wells, keeps the maximum inclination

within desired limits and avoids unnecessarily high dogleg severities.

Tuesday, 9 February 2016

Planning The Well Trajectory - Horizontal wells and Allocation of slots to targets

Horizontal wells

For many applications, the best well profile is one in which the inclination

is built to 90° or even higher.

Allocation of slots to targets

Even this is not always a simple task. From a directional driller's

viewpoint, slots on the North East side of the platform or pad should be

used for wells whose targets are in a North Easterly direction.

Unfortunately there are other considerations (e.g. water injection wells

may have to be grouped together for manifolding requirements). Also, as

more wells are drilled and the reservoir model is upgraded, targets can be

changed or modified.

Inner slots are used to drill to the innermost targets (i.e. targets with the

smallest horizontal distances from the platform) and these wells will be

given slightly deeper kick-off points. The outer slots are used to drill to

targets which are furthest from the platform. These wells will be given

shallow kick-off points and higher build-up rates to keep the maximum

inclination as low as possible.

For many applications, the best well profile is one in which the inclination

is built to 90° or even higher.

Allocation of slots to targets

Even this is not always a simple task. From a directional driller's

viewpoint, slots on the North East side of the platform or pad should be

used for wells whose targets are in a North Easterly direction.

Unfortunately there are other considerations (e.g. water injection wells

may have to be grouped together for manifolding requirements). Also, as

more wells are drilled and the reservoir model is upgraded, targets can be

changed or modified.

Inner slots are used to drill to the innermost targets (i.e. targets with the

smallest horizontal distances from the platform) and these wells will be

given slightly deeper kick-off points. The outer slots are used to drill to

targets which are furthest from the platform. These wells will be given

shallow kick-off points and higher build-up rates to keep the maximum

inclination as low as possible.

Planning The Well Trajectory - Catenary Curve Well Plan

Catenary Curve Well Plan

One suggestion for an efficient well path for directional wells would be to

plan the well as a continuous smooth curve, all the way from KOP to

target. This is the catenary method. A catenary curve is the natural curve

that a cable, chain or any other line of uniform weight assumes when

suspended between two points. A similar suspension of drill string would

also form a catenary curve.

Proponents of the catenary method argue that it results in a smoother

drilled wellbore, that drag and torque are reduced and that there is less

chance of key seating and differential sticking. However, in practice it is

hard to pick BHAs which will continuously give the required gradual rate

of build. It is in reality no easier to follow a catenary curve well plan than a

traditional well plan. Also, the catenary curve method produces a higher

maximum inclination than would result from the build and hold or S type

patterns.

Although the catenary method has been tried, with some success, it is not

widely used and it IS NOT Baker Hughes INTEQ policy to recommend

this type of well profile.

One suggestion for an efficient well path for directional wells would be to

plan the well as a continuous smooth curve, all the way from KOP to

target. This is the catenary method. A catenary curve is the natural curve

that a cable, chain or any other line of uniform weight assumes when

suspended between two points. A similar suspension of drill string would

also form a catenary curve.

Proponents of the catenary method argue that it results in a smoother

drilled wellbore, that drag and torque are reduced and that there is less

chance of key seating and differential sticking. However, in practice it is

hard to pick BHAs which will continuously give the required gradual rate

of build. It is in reality no easier to follow a catenary curve well plan than a

traditional well plan. Also, the catenary curve method produces a higher

maximum inclination than would result from the build and hold or S type

patterns.

Although the catenary method has been tried, with some success, it is not

widely used and it IS NOT Baker Hughes INTEQ policy to recommend

this type of well profile.

Planning The Well Trajectory - Types of Directional Patterns

Types of Directional Patterns

The advent of steerable systems has resulted in wells that are planned and

drilled with complex paths involving 3-dimensional turns. This is

particularly true in the case of re-drills, where old wells are sidetracked and

drilled to new targets.

These complex well paths are harder to drill and the old adage that “the

simplest method is usually the best” holds true. Therefore, most directional

wells are still planned using traditional patterns which have been in use for

many years. Common patterns for vertical projections are shown on the following pages:

Features:·

Shallow kick-off point (KOP)

Build-up section (which may have more than one build up rate)

Tangent section

Applications:

Deep wells with large horizontal displacements

Moderately deep wells with moderate horizontal displacement, where intermediate casing

is not required

Features: There are several variations:

Shallow KOP - Build, hold & drop back to vertical

Build-up section - Build, hold, drop & hold (illustrated above)

Tangent section - Build, hold & continuous drop through reservoir

Drop-off section

Applications: Disadvantages:

Multiple pay zones - Increased torque & drag

Reduces final angle in reservoir - Risk of keyseating

Lease or target limitations - Logging problems due to inclination

Well spacing requirements

Deep wells with small horizontal displacements

Features:

Deep KOP

Build-up section

Short tangent section (optional)

Applications:

Appraisal wells to assess the extent of a newly discovered reservoir

Repositioning of the bottom part of the hole or re-drilling

Salt dome drilling

Disadvantages:

Formations are harder so the initial deflection may be more difficult to achieve

Harder to achieve desired tool face orientation with downhole motor deflection assemblies

(more reactive torque)

Longer trip time for any BHA changes required

On multi-well platforms, only a few wells are given deep kick-off points,

because of the small slot separation and the difficulty of keeping wells

vertical in firmer formation. Most wells are given shallow kick-off points

to reduce congestion below the platform and to minimize the risk of

collisions.

The advent of steerable systems has resulted in wells that are planned and

drilled with complex paths involving 3-dimensional turns. This is

particularly true in the case of re-drills, where old wells are sidetracked and

drilled to new targets.

These complex well paths are harder to drill and the old adage that “the

simplest method is usually the best” holds true. Therefore, most directional

wells are still planned using traditional patterns which have been in use for

many years. Common patterns for vertical projections are shown on the following pages:

Features:·

Shallow kick-off point (KOP)

Build-up section (which may have more than one build up rate)

Tangent section

Applications:

Deep wells with large horizontal displacements

Moderately deep wells with moderate horizontal displacement, where intermediate casing

is not required

Features: There are several variations:

Shallow KOP - Build, hold & drop back to vertical

Build-up section - Build, hold, drop & hold (illustrated above)

Tangent section - Build, hold & continuous drop through reservoir

Drop-off section

Applications: Disadvantages:

Multiple pay zones - Increased torque & drag

Reduces final angle in reservoir - Risk of keyseating

Lease or target limitations - Logging problems due to inclination

Well spacing requirements

Deep wells with small horizontal displacements

Features:

Deep KOP

Build-up section

Short tangent section (optional)

Applications:

Appraisal wells to assess the extent of a newly discovered reservoir

Repositioning of the bottom part of the hole or re-drilling

Salt dome drilling

Disadvantages:

Formations are harder so the initial deflection may be more difficult to achieve

Harder to achieve desired tool face orientation with downhole motor deflection assemblies

(more reactive torque)

Longer trip time for any BHA changes required

On multi-well platforms, only a few wells are given deep kick-off points,

because of the small slot separation and the difficulty of keeping wells

vertical in firmer formation. Most wells are given shallow kick-off points

to reduce congestion below the platform and to minimize the risk of

collisions.

Planning The Well Trajectory - The Target

The Target

The target is usually specified by the geologist, who will not merely define

a certain point as the target but also specify the acceptable tolerance (e.g. a

circle of radius 100 feet having the exact target as its center). Target zones

should be selected as large as possible to achieve the objective. If multiple

zones are to be penetrated, they should be selected so that the planned

pattern is reasonable and can be achieved without causing drilling

problems.

The target is usually specified by the geologist, who will not merely define

a certain point as the target but also specify the acceptable tolerance (e.g. a

circle of radius 100 feet having the exact target as its center). Target zones

should be selected as large as possible to achieve the objective. If multiple

zones are to be penetrated, they should be selected so that the planned

pattern is reasonable and can be achieved without causing drilling

problems.

Planning The Well Trajectory

Planning The Well Trajectory

One area of well planning in which directional companies are closely

involved is the planning of the well trajectory. Again, this is not as simple a

task as it might seem at first glance, particularly on a congested multi-well

platform. There area number of aspects that must be carefully considered

before calculating the final well path.

One area of well planning in which directional companies are closely

involved is the planning of the well trajectory. Again, this is not as simple a

task as it might seem at first glance, particularly on a congested multi-well

platform. There area number of aspects that must be carefully considered

before calculating the final well path.

Well Planning - Field Coordinates

Field Coordinates

Although the coordinates of points on a wellpath could be expressed as

UTM coordinates, it is not normal practice. Instead, a reference point on

the platform or rig is chosen as the local origin and given the coordinates

0,0. On offshore platforms this point is usually the center of the platform.

The Northings and Eastings points on the wells drilled from the platform

are referenced to this single origin. This is important when comparing

positions of wells, in particular for anti-collision analysis.

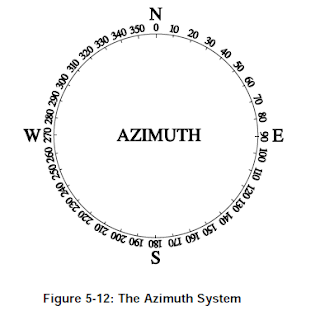

Direction Measurements

Survey tools measure the direction of the wellbore on the horizontal plane

with respect to North reference, whether it is True or Grid North. There are

two systems:

Azimuth.

In the azimuth system, directions are expressed as a clockwise angle from

0° to 359.99°, with North being 0°.

Quadrant Bearings

In the quadrant system , the directions are expressed as angles

from 0°-90° measured from North in the two Northern quadrants and from

South in the Southern quadrants. The diagram in Figure 5-14 illustrates

how to convert from the quadrant system to azimuth, and vice versa.

Although the coordinates of points on a wellpath could be expressed as

UTM coordinates, it is not normal practice. Instead, a reference point on

the platform or rig is chosen as the local origin and given the coordinates

0,0. On offshore platforms this point is usually the center of the platform.

The Northings and Eastings points on the wells drilled from the platform

are referenced to this single origin. This is important when comparing

positions of wells, in particular for anti-collision analysis.

Direction Measurements

Survey tools measure the direction of the wellbore on the horizontal plane

with respect to North reference, whether it is True or Grid North. There are

two systems:

Azimuth.

In the azimuth system, directions are expressed as a clockwise angle from

0° to 359.99°, with North being 0°.

Quadrant Bearings

In the quadrant system , the directions are expressed as angles

from 0°-90° measured from North in the two Northern quadrants and from

South in the Southern quadrants. The diagram in Figure 5-14 illustrates

how to convert from the quadrant system to azimuth, and vice versa.

Friday, 5 February 2016

Well Planning - Reference Systems and Coordinates, (3) Azimuth Reference Systems

Azimuth Reference Systems

For directional surveying there are three azimuth reference systems:

• Magnetic North

• True (Geographic) North

• Grid North

All “magnetic-type” tools give an azimuth (hole direction) referenced to

Magnetic North. However, the final calculated coordinates are always

referenced to either True North or Grid North.

True (Geographic) North

This is the direction of the geographic North Pole which lies on the Earth’s

axis of rotation. Direction is shown on maps using meridians of longitude.

Grid North

Drilling operations occur on a curved surface (i.e, the surface of the Earth)

but when calculating horizontal plane coordinates a flat surface is assumed.

Since it is not possible to exactly represent part of the surface of a sphere

on a flat well plan, corrections must be applied to the measurements. To do

this, different projection systems which can be used.

UTM System

One example of a grid system is the Universal Transverse Mercator (UTM)

System. In transverse mercator projection, the surface of the spheroid

chosen to represent the Earth is wrapped in a cylinder which touches the

spheroid along a chosen meridian. (A meridian is a circle running around

the Earth passing through both North and South geographic poles.)

These meridians of longitude converge towards the North Pole and do not

produce a rectangular grid system. The grid lines on a map form the

rectangular grid system, the Northerly direction of which is determined by

one specified meridian of longitude. This “Grid North” direction will only

be identical to “True North” on a specified meridian.

For directional surveying there are three azimuth reference systems:

• Magnetic North

• True (Geographic) North

• Grid North

All “magnetic-type” tools give an azimuth (hole direction) referenced to

Magnetic North. However, the final calculated coordinates are always

referenced to either True North or Grid North.

True (Geographic) North

This is the direction of the geographic North Pole which lies on the Earth’s

axis of rotation. Direction is shown on maps using meridians of longitude.

Grid North

Drilling operations occur on a curved surface (i.e, the surface of the Earth)

but when calculating horizontal plane coordinates a flat surface is assumed.

Since it is not possible to exactly represent part of the surface of a sphere

on a flat well plan, corrections must be applied to the measurements. To do

this, different projection systems which can be used.

UTM System

One example of a grid system is the Universal Transverse Mercator (UTM)

System. In transverse mercator projection, the surface of the spheroid

chosen to represent the Earth is wrapped in a cylinder which touches the

spheroid along a chosen meridian. (A meridian is a circle running around

the Earth passing through both North and South geographic poles.)

These meridians of longitude converge towards the North Pole and do not

produce a rectangular grid system. The grid lines on a map form the

rectangular grid system, the Northerly direction of which is determined by

one specified meridian of longitude. This “Grid North” direction will only

be identical to “True North” on a specified meridian.

Well Planning - Reference Systems and Coordinates, (2) Inclination References

Inclination References

The inclination of a well-bore is the angle (in degrees) between the vertical

and the well bore axis at a particular point. The vertical reference is the

direction of the local gravity vector and could be indicated by a plumb bob.

The inclination of a well-bore is the angle (in degrees) between the vertical

and the well bore axis at a particular point. The vertical reference is the

direction of the local gravity vector and could be indicated by a plumb bob.

Well Planning - Reference Systems and Coordinates.- (1) Depth References

Depth References

During the course of a directional well, there are two kinds of depths:

• Measured Depth (MD) is the distance measured along the actual

course of the borehole from the surface reference point to the survey

point. This depth is always measured in some way, for example, pipe

tally, wireline depth counter, or mud loggers depth counter.

• True Vertical Depth (TVD) is the vertical distance from the depth

reference level to a point on the borehole course. This depth is always

calculated from the deviation survey data.

In most drilling operations the rotary table elevation is used as the working

depth reference. The abbreviation BRT (below rotary table) and RKB

(rotary kelly bushing) are used to indicate depths measured from the rotary

table. This can also be referred to as derrick floor elevation. For floating

drilling rigs the rotary table elevation is not fixed and hence a mean rotary

table elevation has to be used.

In order to compare individual wells within the same field, a common

depth reference must be defined and referred to (e.g. When drilling a relief

well into a blow-out well, the difference in elevation between the

wellheads has to be accurately known). Offshore, mean sea level (MSL) is

sometimes used. Variations in actual sea level from MSL can be read from

tide tables or can be measured.

During the course of a directional well, there are two kinds of depths:

• Measured Depth (MD) is the distance measured along the actual

course of the borehole from the surface reference point to the survey

point. This depth is always measured in some way, for example, pipe

tally, wireline depth counter, or mud loggers depth counter.

• True Vertical Depth (TVD) is the vertical distance from the depth

reference level to a point on the borehole course. This depth is always

calculated from the deviation survey data.

In most drilling operations the rotary table elevation is used as the working

depth reference. The abbreviation BRT (below rotary table) and RKB

(rotary kelly bushing) are used to indicate depths measured from the rotary

table. This can also be referred to as derrick floor elevation. For floating

drilling rigs the rotary table elevation is not fixed and hence a mean rotary

table elevation has to be used.

In order to compare individual wells within the same field, a common

depth reference must be defined and referred to (e.g. When drilling a relief

well into a blow-out well, the difference in elevation between the

wellheads has to be accurately known). Offshore, mean sea level (MSL) is

sometimes used. Variations in actual sea level from MSL can be read from

tide tables or can be measured.

Well Planning - Reference Systems and Coordinates.

Reference Systems and Coordinates

With the exception of Inertial Navigation Systems, all survey systems

measure inclination and azimuth at a particular measured depth (depths

measured “along hole”). These measurements are tied to fixed reference

systems so that the course of the borehole can be calculated and recorded.

These reference systems include:

• Depth references

• Inclination references

• Azimuth references

With the exception of Inertial Navigation Systems, all survey systems

measure inclination and azimuth at a particular measured depth (depths

measured “along hole”). These measurements are tied to fixed reference

systems so that the course of the borehole can be calculated and recorded.

These reference systems include:

• Depth references

• Inclination references

• Azimuth references

Well Planning - Introduction

Well Planning

Introduction

There are many aspects involved in well planning, and many individuals

from various companies and disciplines are involved in designing various

programs for the well (mud program, casing program, drill string design,

bit program, etc). A novel approach to well planning is one where the

service contractors become equally involved in their area of expertise.

This section will concentrate on those aspects of well planning which have

always been the province of directional drilling companies.

Introduction

There are many aspects involved in well planning, and many individuals

from various companies and disciplines are involved in designing various

programs for the well (mud program, casing program, drill string design,

bit program, etc). A novel approach to well planning is one where the

service contractors become equally involved in their area of expertise.

This section will concentrate on those aspects of well planning which have

always been the province of directional drilling companies.

Thursday, 4 February 2016

Shoreline Drilling.

Shoreline Drilling.

In the case where a reservoir lies offshore but quite close to land, the most

economical way to exploit the reservoir may be to drill directional wells

from a land rig on the coast.

These are only some of the many applications of directional drilling.

Although it is not a new concept, one type of directional drilling, horizontal

drilling, is the fastest growing branch of drilling, with major advances

occurring in tools and techniques. As with directional drilling, there are

numerous specific applications for horizontal drilling.

In the case where a reservoir lies offshore but quite close to land, the most

economical way to exploit the reservoir may be to drill directional wells

from a land rig on the coast.

These are only some of the many applications of directional drilling.

Although it is not a new concept, one type of directional drilling, horizontal

drilling, is the fastest growing branch of drilling, with major advances

occurring in tools and techniques. As with directional drilling, there are

numerous specific applications for horizontal drilling.

Wednesday, 3 February 2016

Sidetracking

Sidetracking

Sidetracking out of an existing wellbore is another application of

directional drilling. This is done to bypass an obstruction (“fish”) in the

original wellbore, to explore the extent of a producing zone in a certain

sector of a field, or to sidetrack a dry hole to a more promising target.

Wells are also sidetracked to access more reservoir by drilling a horizontal

hole section from the existing well bore.

Sidetracking out of an existing wellbore is another application of

directional drilling. This is done to bypass an obstruction (“fish”) in the

original wellbore, to explore the extent of a producing zone in a certain

sector of a field, or to sidetrack a dry hole to a more promising target.

Wells are also sidetracked to access more reservoir by drilling a horizontal

hole section from the existing well bore.

Multiple wells from offshore structures

Multiple wells from offshore structures

The most common application of directional drilling techniques is in

offshore drilling. Many oil and gas deposits are situated well beyond the

reach of land based rigs. Drilling a large number of vertical wells from

individual platforms is both impractical and uneconomical. The obvious

approach for a large oilfield is to install a fixed platform on the seabed,

from which many directional boreholes can be drilled. The bottomhole

locations of these wells are carefully spaced for optimum recovery.

In conventional development, wells cannot be drilled until the platform has

been constructed and installed. This can mean a delay of several years

before production begins. Such delay scan be considerably reduced by predrilling